Flooring fundamentals

What you should know about flooring

Wood is a dynamic medium. Like all organic materials, it has character and quirks, responds to its environment, and changes over time. Because of its "personality," wood should be treated with understanding and a certain amount of care. For wood flooring professionals, knowing about the properties of wood in general, as well as those of individual wood species, is critical to proper installation. For consumers, it's important to have realistic expectations about how wood will perform. Most wood used for flooring is essentially a byproduct of more expensive wood-consuming industries (furniture manufacture, for example), so it is usually not the highest grade of lumber. However, it is quite economical in comparison.

This publication prepared by National Wood Flooring Association provides an overview of the mechanical and physical properties of wood, followed by more detailed information on several species used in flooring. In selecting the species described, the aim has been to offer a fair sampling of some of today's most popular woods. Other species may be included in later editions of this publication.

The character of woodTop of page

As a flooring material, wood is superior to vinyl or carpet, both practically and aesthetically. A solid wood floor is more than a covering; it adds strength and stability to the floor system. A one-inch thickness of wood has the same insulating value as 15 inches of concrete. Wood is durable and long-lasting - occasional sanding and refinishing essentially results in a brand-new floor. Wood floors don't retain mildew or absorb dust, simplifying cleaning.

Perhaps the most appealing characteristics of wood flooring, though, are its attractive appearance and natural warmth. A beautiful wood floor can enliven a drab room, enhance any architectural style, complement furniture and design schemes, and add value to any home or building.

A combination of qualities should be considered when selecting a species for flooring: appearance-related attributes such as texture, grain and color, as well as mechanical properties like dimensional stability, durability, machinabiliry and ease in finishing; and finally, availability and cost.

Properties affecting appearanceTop of page

Many different factors, from the nature of the living tree to the way the lumber is sawed, affect the way the finished floor will look.

HEARTWOOD, SAPWOOD

Heartwood is the older, harder central portion of a tree. It usually contains deposits of various materials that frequently give it a darker color than sapwood. It is denser, less permeable and more durable than the surrounding sapwood.

Sapwood is the softer, younger outer portion of a tree that lies between the cambium (formative layer just under the bark) and the heartwood. It is more permeable, less durable and usually lighter in color than the heartwood.

The relative amounts of heartwood and sapwood in a flooring batch may affect the way it accepts stain and finish and, therefore, the finished appearance of the floor. In general, quartersawn and rift-sawn flooring will contain less sapwood than plainsawn flooring (see 'Types of saw cut," next page), and will tend to have a straighter grain and more uniform appearance. Heartwood is also more dimensionally stable than sapwood, so flooring with a high percentage of heartwood will shrink and swell less than flooring that is mostly sapwood.

WOOD GRAIN AND TEXTURE

Grain and "texture" are loosely used to describe similar properties of wood. Grain is often used in reference to annual growth rings, as in "fine" or "coarse" grain; it is also used to indicate the direction of fibers, as in straight, spiral and curly grain. The direction of the grain, as well as the amount of figuring in the wood, can affect the way it is sanded and sawed.

Grain is also described as being either "open" or "closed," referring to the relative size of the pores, which affects the way a wood accepts stain and finishes.

Texture usually refers to the finer structure of the wood, rather than to the annual rings. It is sometimes used to combine the concepts of density and degree of contrast between spring wood and summer wood in the annual growth rings.

Some wood grain terminologyTop of page

Annual rings: Most species grown in temperate climates produce visible annual growth rings that show the difference in density and color between wood formed early and that formed late in the growing season. The inner part of the growth ring, formed first, is called "spring wood"; the outer part, formed later in the season, is called "summer wood." Spring wood is characterized by cells having relatively large cavities and thin walls. Summer wood cells have smaller cavities and thicker walls, and consequently are more dense than those in spring wood. The growth rings, when exposed by conventional sawing methods, provide the grain or characteristic pattern of the wood. The distinguishing features among the various species result in part, then, from differences in growth-ring formation. And within species, natural variations in growth ensure the unique character and beauty of each piece of wood.

Annual rings: Most species grown in temperate climates produce visible annual growth rings that show the difference in density and color between wood formed early and that formed late in the growing season. The inner part of the growth ring, formed first, is called "spring wood"; the outer part, formed later in the season, is called "summer wood." Spring wood is characterized by cells having relatively large cavities and thin walls. Summer wood cells have smaller cavities and thicker walls, and consequently are more dense than those in spring wood. The growth rings, when exposed by conventional sawing methods, provide the grain or characteristic pattern of the wood. The distinguishing features among the various species result in part, then, from differences in growth-ring formation. And within species, natural variations in growth ensure the unique character and beauty of each piece of wood.

Figure: The pattern produced in a wood surface by annual growth rings, rays, knots, and deviations from regular grain.

Medullary Rays: Medullary rays extend radially from the core of the tree toward the bark. They vary in height from a few cells in some species, to four or more inches in the oaks; they're responsible for the flake effect common to the quartersawn lumber in certain species.

Tangential Grain: Usually called flat grain; easily recognized by its parabolic (arched) effect. Lumber is considered "flat-grained" when the annual growth rings make an angle of less than 45 degrees with the wide surface of the board.

Radial Grain: Known as vertical or edge grain; generally more dimensionally stable than flat grain - that is, vertical-grain boards are less likely to expand or contract in width with changes in moisture. Lumber is considered "vertical-grained" when the annual growth rings make an angle of 45 to 90 degrees with the wide surface of the board. (Note: In hardwoods, plainsawn lumber generally contains mostly flat-grained wood, while quartersawn lumber is nearly all vertical-grained. In softwood lumber, the terms "flat-grained" and "vertical-grained" are used instead of the terms "plainsawn" and "quartersawn," respectively. See "Types of saw cut" below.)

Interlocked Grain: Grain in which the fibers may slope in a right-handed direction for several years, in a left-handed direction for several years, back to right-handed, and so on. A high degree of interlocked grain may make a wood difficult to machine.

Types of saw cutTop of page

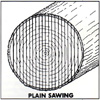

Lumber is either plainsawn, quartersawn or riftsawn.

Plainsawing is the most common and least expensive method of sawing; most wood flooring is cut this way. Plainsawn lumber is obtained by making the first saw cut on a tangent to the circumference of the log and remaining cuts parallel to the first. This method is the most economical, because it provides the widest boards and results in the least waste.

Plainsawing is the most common and least expensive method of sawing; most wood flooring is cut this way. Plainsawn lumber is obtained by making the first saw cut on a tangent to the circumference of the log and remaining cuts parallel to the first. This method is the most economical, because it provides the widest boards and results in the least waste.

Since most of the lumber produced by plainsawing is flat-grained, with some vertical-grained wood included, plainsawn lumber will tend to contain more variation within and among boards than quartersawn lumber, in which nearly all of the wood is vertical-grained. Also, since flat-grained wood is less dimensionally stable than vertical-grained, plainsawn lumber will tend to expand and contract more across the width of the boards than quartersawn lumber.

Other physical differences to consider when choosing plainsawn lumber rather than quartersawn:

- Figure patterns resulting from the annual rings and some other types of figures are usually brought out more conspicuously by plainsawing.

- Shakes and pitch pockets, when present, extend through fewer boards.

In quartersawing, lumber is produced by first quartering the log and then sawing perpendicular to the growth rings. Quartersawing produces relatively narrow boards, nearly all vertical-grained, and creates more waste, making quartersawn lumber more expensive than plainsawn. However, much quarter-sawn wood is obtained by culling the vertical-grained wood that naturally results from plainsawing. For reasons other than cost, most people prefer quartersawn wood, although some people favor the greater variety in figuring produced in plainsawing.

In quartersawing, lumber is produced by first quartering the log and then sawing perpendicular to the growth rings. Quartersawing produces relatively narrow boards, nearly all vertical-grained, and creates more waste, making quartersawn lumber more expensive than plainsawn. However, much quarter-sawn wood is obtained by culling the vertical-grained wood that naturally results from plainsawing. For reasons other than cost, most people prefer quartersawn wood, although some people favor the greater variety in figuring produced in plainsawing.

Other physical factors to keep in mind when choosing quartersawn lumber over plainsawn:

- It twists and cups less.

- It surface-checks and splits less during seasoning and in use.

- Raised grain produced by separation in the annual growth

- rings does not appear as pronounced.

- It wears more evenly.

- Figuring due to pronounced rays, interlocked and wavy grain are brought out more conspicuously.

- Sapwood appears only at the edges, and is limited to the width of the sapwood in the log.

Riftsawing is similar to quartersawing, with many of the same advantages and limitations. It accentuates the vertical grain and minimizes the flake effect common in quartersawn oak. The angle of the cut is changed slightly so that fewer saw cuts are parallel to the medullary rays, which are responsible for the flake effect. Riftsawing creates more waste than quartersawing, making it generally more expensive.

Mechanical propertiesTop of page

MOISTURE CONTENT AND DIMENSIONAL STABILITY

Moisture plays a large part in how wood behaves, both during the machining process and after installation. Installers would do well to study moisture's effect on wood in some detail; however, a brief discussion is worthwhile here.

Moisture content is defined as the weight of water in wood expressed as a percentage of the weight of oven-dry wood. Weight, shrinkage, strength and other properties depend on the moisture content of wood. In trees, moisture content may be as much as 200 percent of the weight of wood substance. After harvesting and milling, the wood will be dried to the proper moisture content for its end use.

Wood is dimensionally stable when the moisture content is above the fiber saturation point (usually about 30 percent moisture content). Below that, wood changes dimension when it gains or loses moisture.

The ideal moisture content for flooring installation can vary from an extreme of 4 to 18 percent, depending on the wood species, the geographic location of the end product and the time of year. Most oak flooring, for example, is milled at 6 to 9 percent. Before installation, solid wood flooring should be acclimated to the area in which it is to be used, then tested with a moisture meter to ensure the proper moisture content. (Note: Laminated flooring tends to be more dimensionally stable than solid flooring, and does not require acclimation prior to installation.)

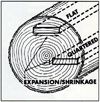

Different woods exhibit different moisture stability factors, but they generally shrink and swell the most in the direction of the annual growth rings (tangen-tially), about half as much across the rings (radially) and only slightly along the grain (longitudinally). This means that plainsawn flooring will tend to shrink and swell more in width than quartersawn flooring, and that most flooring will not shrink or swell much in length.

The individual species descriptions that follow include an indication of dimensional stability, from "below average" to "excellent," as well as a comparison to red oak. For example, mesquite (the most dimensionally stable species in this publication) is rated as "excellent," with a notation that it is 65 percent more stable than red oak - that is, mesquite is likely to shrink or swell 65 percent less. The percentages noted are based on comparing a factor called the "dimensional change coefficient" of each species with that of red oak. Red oak was chosen as the benchmark because of its widespread familiarity and use in the flooring industry. For a comparison of the relative dimensional stability of several species, measured by the dimensional change coefficient, refer to the chart.

The individual species descriptions that follow include an indication of dimensional stability, from "below average" to "excellent," as well as a comparison to red oak. For example, mesquite (the most dimensionally stable species in this publication) is rated as "excellent," with a notation that it is 65 percent more stable than red oak - that is, mesquite is likely to shrink or swell 65 percent less. The percentages noted are based on comparing a factor called the "dimensional change coefficient" of each species with that of red oak. Red oak was chosen as the benchmark because of its widespread familiarity and use in the flooring industry. For a comparison of the relative dimensional stability of several species, measured by the dimensional change coefficient, refer to the chart.

For wood flooring professionals, it's important to inform end users about the normal behavior of wood in relation to moisture. Most solid wood flooring will contract during periods of low humidity (during the heating season, for example), sometimes leaving noticeable cracks between boards. To minimize this effect, users should stabilize the environment of the building through temperature and humidity control.

The ideal moisture content for flooring installation can vary from an extreme of 4 to 18 percent, depending on the wood species, the geographic location of the end product and the time of year. Most oak flooring, for example, is milled at 6 to 9 percent. Before installation, solid wood flooring should be acclimated to the area in which it is to be used, then tested with a moisture meter to ensure the proper moisture content. (Note: Laminated flooring tends to be more dimensionally stable than solid flooring, and does not require acclimation prior to installation.)

Different woods exhibit different moisture stability factors, but they generally shrink and swell the most in the direction of the annual growth rings (tangen-tially), about half as much across the rings (radially) and only slightly along the grain (longitudinally). This means that plainsawn flooring will tend to shrink and swell more in width than quartersawn flooring, and that most flooring will not shrink or swell much in length.

The individual species descriptions that follow include an indication of dimensional stability, from "below average" to "excellent," as well as a comparison to red oak. For example, mesquite (the most dimensionally stable species in this publication) is rated as "excellent," with a notation that it is 65 percent more stable than red oak - that is, mesquite is likely to shrink or swell 65 percent less. The percentages noted are based on comparing a factor called the "dimensional change coefficient" of each species with that of red oak. Red oak was chosen as the benchmark because of its widespread familiarity and use in the flooring industry. For a comparison of the relative dimensional stability of several species, measured by the dimensional change coefficient, refer to the chart.

For wood flooring professionals, it's important to inform end users about the normal behavior of wood in relation to moisture. Most solid wood flooring will contract during periods of low humidity (during the heating season, for example), sometimes leaving noticeable cracks between boards. To minimize this effect, users should stabilize the environment of the building through temperature and humidity control.

HARDNESS AND DURABILITY

Probably the most important strength property for wood used in flooring applications is its side hardness, also known as Janka hardness. Side hardness represents the resistance of wood to wear, denting and marring. It is measured by the load required to embed a 0.444-inch steel ball to one-half its diameter in the wood. Janka hardness ratings are generally based on an average of tests on both tangential and radial (plainsawn and quartersawn) samples. A comparison chart of the Janka hardness ratings for each of the species described in this chapter appears farther in this article. Also, the individual species descriptions include a percentage comparison to indicate each species hardness relative to Northern red oak.

MACHINING

The workability of a wood depends on several factors, including density, extent of interlocked or variable grain, hard mineral deposits, and tensions in wood that may cause fibrous and fuzzy surfaces. The degree of checking and separation present will also affect machining ease.

Interlocked grain is characteristic of many tropical species and causes problems in planing quartersawn boards unless feed rates, cutting angles and sharpness of knives are carefully controlled.

Hard deposits in the cells, such as calcium carbonate and silica, may have a pronounced dulling effect on cutting tools. This effect generally increases as wood is dried to normal working requirements.

NAILING

When nailing some of the denser woods with hand or air nailers, installers may encounter splitting tongues, as well as failure to secure the fastener even after repeated attempts. This can sometimes be corrected by changing the angle of the nail's point of entry. On certain exceptionally dense species, pilot holes may have to be drilled to ease nailing. Blunting the ends of fasteners may also help prevent splitting.

Though dense, heavy woods normally offer higher nail-withdrawal resistance, less dense species allow the use of more and larger-diameter fasteners to compensate for their lower holding ability.

SANDING

Some wood species are highly resinous and tend to clog sandpaper. When working with such species, it may be necessary to use a coarser grit of sandpaper than normal, or to change the sandpaper more often than with other species.

Also, the wood dust created by sanding some species tends to cause an allergic reaction in some people. This is more likely to occur with imported species than with domestic. However, even North American oak has been known to cause a skin rash or respiratory difficulties in some people. Where applicable, known tendencies to cause allergic reactions are noted.

As a precaution, flooring mechanics should wear long sleeves, dust masks and eye protection when sanding.

To test for possible allergic reaction to a species, perform a skin-patch test by placing a small amount of wood dust under a round adhesive bandage on the inside of the forearm. If serious skin irritation is present when the bandage is removed after 24 hours, consider not working with that species.

FINISHING

Some woods, especially imports, contain oils and chemical compounds that may adversely react with certain types of finishes to inhibit drying, dramatically change the color of the wood, or both. In addition, many finish formulations are undergoing continual change as their manufacturers move to comply with evolving environmental regulations, making hard-and-fast finishing rules difficult to come by.

Water-based urethane finishes have gained in popularity over the past 10 years. They are quick-drying and increasingly durable. Some flooring professionals also believe they tend to inhibit the color change certain woods undergo over time, which may be desirable. These finishes tend to leave wood lighter in color. Non-ambering urethanes are often recommended for finishing white or pastel floors.

Water-based finishes tend to adhere well to most woods, including exotics, whereas some solvent-based finishes have adhesion, drying or color change problems with woods like African cherry, rosewoods, teak, Brazilian and African walnut, purpleheart. padauk and wenge.

For floors that are to be stained to alter the natural color of the wood, flooring professionals should be aware that some species (hard maple, pine and fir. for example) do not accept stain as readily or as evenly as other species.

A grain filler is sometimes used for wood species with large pores, such as oak or walnut when smooth finish is desired.

When working with a new species for the first time, installers should test stains and finishes on a small sample of flooring before attempting an installation.

Relative hardness of selected wood flooring speciesTop of page

The Janka (or side) hardness test measures the force required to embed a .444-inch steel ball to half its diameter in wood. It is one of the best measures of the ability of a wood species to withstand denting and wear. By the same token, it is also a good indicator of how hard or easy a species is to saw or nail. Northern red oak, for example, has a Janka hardness rating of 1290. Brazilian cherry, with a rating of 2350, is nearly twice as hard. If you're accustomed to working with red oak and decide to tackle a job with Brazilian cherry, you can expect it to be much harder to cut and nail.

The Janka (or side) hardness test measures the force required to embed a .444-inch steel ball to half its diameter in wood. It is one of the best measures of the ability of a wood species to withstand denting and wear. By the same token, it is also a good indicator of how hard or easy a species is to saw or nail. Northern red oak, for example, has a Janka hardness rating of 1290. Brazilian cherry, with a rating of 2350, is nearly twice as hard. If you're accustomed to working with red oak and decide to tackle a job with Brazilian cherry, you can expect it to be much harder to cut and nail.

Relative stability of selected wood flooring speciesTop of page

The numbers in the chart reflect the dimensional change coefficient for the various species, measured as tangential shrinkage or swelling within normal moisture content limits of 6-14 percent. Tangential change values will normally reflect changes in plainsawn wood. Quartersawn wood will usually be more dimensionally stable than plainsawn.

The numbers in the chart reflect the dimensional change coefficient for the various species, measured as tangential shrinkage or swelling within normal moisture content limits of 6-14 percent. Tangential change values will normally reflect changes in plainsawn wood. Quartersawn wood will usually be more dimensionally stable than plainsawn.

The dimensional change coefficient can be used to calculate expected shrinkage or swelling. Simply multiply the change in moisture content by the change coefficient, then multiply by the width of the board.

Example: A mesquite (change coefficient = .00129) board 5 inches wide experiences a moisture content change from 6 to 9 percent - a change of 3 percentage points. CalcukxUorv 3 x .00129 = .00387 x 5 = .019 inches.

In actual practice, however, change would be diminished in a complete floor, as the boards' proximity to each other tends to restrain movement. The chart is best used for comparison.

Although some tropical woods such as Australian cypress, Brazilian cherry, merbau and wenge appear in this chart to have excellent moisture stability compared to domestic oak, actual installations of many of these woods have demonstrated significant movement in use. To avoid problems later, extra care should be taken to inform potential users of these tendencies prior to purchase.

Relative cost of selected wood flooring speciesTop of page

How to use this chart: Costs for any species may vary according to current availability, location and other market factors. This chart is intended only to provide a comparison scale. Each species has been assigned a multiplier to be applied to the cost of plainsawn select red oak, chosen as the benchmark because of its widespread use in the flooring industry. Brazilian cherry, for example, has been assigned a cost multiplier of 1.30. If you know the cost of plainsawn select red oak, multiply by 1.3, and you have some idea what Brazilian cherry might cost. Please keep in mind, however, that these figures are only estimates; actual costs can vary greatly by locale, time of year and flooring style.

How to use this chart: Costs for any species may vary according to current availability, location and other market factors. This chart is intended only to provide a comparison scale. Each species has been assigned a multiplier to be applied to the cost of plainsawn select red oak, chosen as the benchmark because of its widespread use in the flooring industry. Brazilian cherry, for example, has been assigned a cost multiplier of 1.30. If you know the cost of plainsawn select red oak, multiply by 1.3, and you have some idea what Brazilian cherry might cost. Please keep in mind, however, that these figures are only estimates; actual costs can vary greatly by locale, time of year and flooring style.